Connectors

Next-Gen Connector Upgrade for the Standard RJ45

The Ethernet connector, better known as the RJ45, has become a ubiquitous component of modern digital infrastructure, serving as the backbone for data and voice equipment connectivity. With the rapid expansion of digitalization and the Internet of Things (IoT), the demand for more robust, efficient, and advanced Ethernet solutions has soared. To address this burgeoning demand, the industry is now witnessing an exciting transformation: the evolution from the standard RJ45 to the next-generation connector.

The RJ45 Connector

To better understand this popular Ethernet connectivity connector, let’s first break down its name. The RJ prefix stands for “Registered Jack” and means this interface is standardized for connecting data and voice equipment, while 45 designates the specific installation application. This connector is more technically referred to as an eight-position, eight-contact (8P8C) modular plug.

There are a variety of 8P8C connectors, in which eight wires are inserted into the eight positions, spaced at intervals of 1mm, but the RJ45 is the most common for twisted-pair Ethernet cabling.

RJ45 connectors have two pinouts—T568A and T568B. The T568B pinout has become a more popular configuration for performing data transfer. Figure 1 shows the differences in color conventions and wiring pinouts between these two standards.

Figure 1: Color conventions of the wiring pinout for the T568A RJ45 connector and T568B RJ45 connector (Source: shurik76- stock.adobe.com)

Key Drivers of Industrial Ethernet Deployment

The evolution of next-gen Ethernet communication connectors from the standard RJ45 stems from the rise of IoT, the growing need for higher data rates, and stringent factory automation conditions.

Transition to Higher Data Rates

We are in the Fourth Industrial Revolution (Industry 4.0), which combines traditional manufacturing processes with smart technology. This joint effort of the old and new is creating a more streamlined and efficient system, that is, one that is now run on data. The world's data production has grown so fast that more than 90 percent of all the world’s data has been produced within the last three years1. Data production has reached 2.5 quintillion bytes within these three years. This means that the industrial sector needs to move on to higher and higher data rates going forward to keep up.

Industry 4.0 is leading to the merger of Operation Technology (OT) and Information Technology (IT). Reaching this point, however, will necessitate a renovation of the manufacturing process along with a data architecture that will be able to absorb the vast volumes of real-time data generated by IoT sensors and other devices. This means enabling nano-second control of the whole environment. The prime issue here is time; all elements in the production process must swiftly comply with and be controlled by a central management system.

Conditions in Factory Automation

Various challenges in the demanding factory automation environment necessitate a transition towards next-gen connector solutions like the Hirose ix Industrial™. These challenges include:

- EMI (Electromagnetic Interference): Electrical noise is pervasive in factory settings. RJ45 connector solutions must have Electromagnetic Compatibility (EMC) and be adequately shielded against EMI to ensure reliable operation. A jack and plug solution are needed to protect the Ethernet system from EMI interference while preventing interference with other nearby systems.

- Environmental Conditions: There are harsh environments found in industrial installations compared to an office environment. Within a tough factory environment, a plastic RJ45 connector can possibly get crushed or even stripped by such things as a forklift truck. The Hirose ix connector will mitigate most of these dangers because of its robust construction.

Introducing the Hirose ix Industrial™ Solution

Hirose has set the benchmark for innovation by developing a compact interface connector engineered with a focus on stability. These connectors offer exceptional resistance to shock and vibration, ensuring optimal performance even in demanding environments.

The ix Industrial™ connector from Hirose is a game changer in the industrial sector (Figure 2). This innovative connector is roughly 75 percent smaller than the conventional RJ45, offers greater stability with high resistance to shock and vibration, and has a robust design that can endure thousands of mating cycles. In addition to being IEC 61076-3-124 standard compliant, it also supports the Cat.6A (10Gbps) cable standard, ensuring stable high-speed transmission.

Figure 2: Hirose Electric ix Industrial Ethernet Mating Interfaces are IEC 61076-3-124 standard compliant, reducing installation space by 75 percent compared to traditional RJ45 solutions (Source: Mouser Electronics)

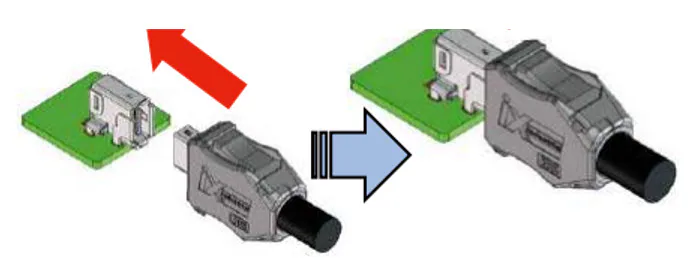

These connectors have a single-action lock design, offering high EMC resistance and ensuring secure data transmission (Figure 3). Their compatibility with through-hole mounting ensures a durable connection on a PC board.

Figure 3: The Hirose ix Industrial’s single-action lock design allows for effortless operation and provides a clear tactile click to prevent incomplete mating (Source: Hirose and Mouser)

Beyond this, Hirose Electric ix Industrial Ethernet Mating Interfaces boast a 10Gbps transmission rate and a 10mm pitch parallel mounting, perfect for higher connection density and daisy-chaining. These versatile connectors are well-suited to industrial machinery, with an optimized shielding design for noisy environments and resistance to prying.

Additional features include two keying options and two contact plating options, providing further customization. Hirose also offers a range of tools, such as electric crimpers, cable clamps, punches, dies, and other crimping tools.

These compact I/O connectors find applications across various fields, including, but not limited to, factory automation, robotics, data centers, security systems, and transportation. As we look to the future, Hirose's innovative solutions are set to play a pivotal role in shaping the next generation of Ethernet connectivity.

Conclusion

A transformative shift is taking place in Ethernet technology, transitioning from the standard RJ45 connector to next-gen connectors, such as Hirose's ix Industrial Ethernet Mating Interfaces.

This stride in Ethernet connectivity paves the way for more resilient, efficient, and compact solutions. Whether it is factory automation, robotics, data centers, security systems, or transportation, these innovative and robust ix Industrial connectors promise to revolutionize the way we navigate the landscape of digitalization and the IoT.